The paper「Effect of dealloying rate on transformation behavior during liquid metal dealloying」...

- 2021년 1월 19일

- 1분 분량

The paper "Effect of dealloying rate on transformation behavior during liquid metal dealloying" has been published at Journal of Alloys and Compounds.

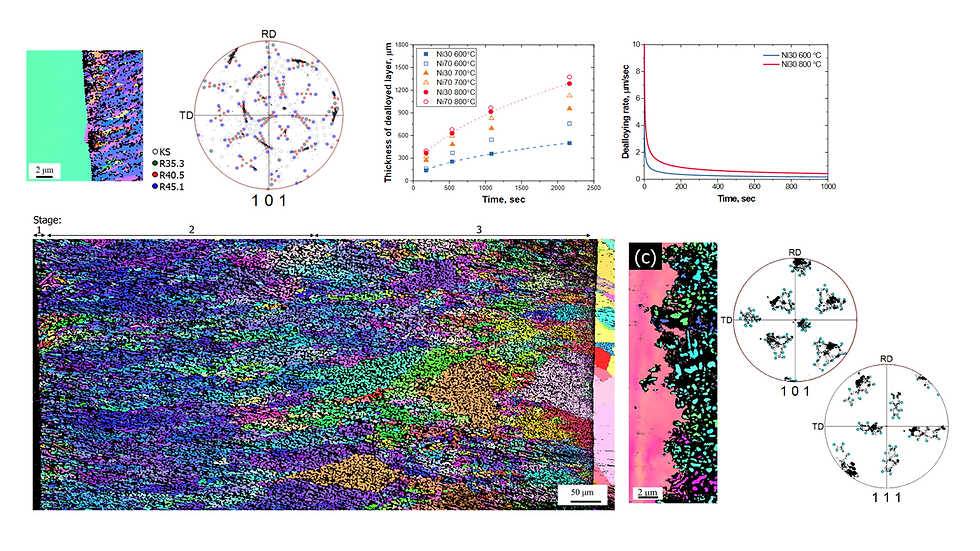

Liquid metal dealloying is a new process that can be applied to synthesize non-noble porous materials by preventing oxidation in a utilized metallic melt. The effect of dealloying rate was investigated by electron backscattered diffraction at the reaction layer at various temperatures (600–800 °C) using (FeCo)xNi100−x precursors in a Mg melt. FeCo ligaments transformed via different mechanisms depending on dealloying rate, temperature, and concentration of Ni. At the initial stage near the precursor surface, random texture was dominant in all cases. When the dealloying rate slowed down at 600 °C and 800 °C, the parent face-centered cubic grain structure played a significant role. The second stage differed depending on the dealloying conditions, including formation of <111>//normal direction fiber texture or an unknown specific orientation relationship. The orientation relationships also differed in the third stage. At 800 °C, the dealloying rate should be much slower than that at 600 °C to appear the third stage of the specific orientation relationship.

Highlights

•Dealloying rate strongly influences transformation mechanism in liquid metal dealloying.

•When the dealloying rate is very high, random texture normally develops.

•Ni70 showed a larger extended first stage of random texture than Ni30 and Ni50.

•Governing orientation relationship depended on dealloying rate of Ni50 at 600 °C.

•At 800 °C, fiber texture altered to an orientation relationship when dealloying rate decreased.

댓글